Indisputably, mechanical seal failure is the most common cause of pump downtime. Operators and engineers in plants of all sizes and industries will vouch for it. In this blog, we will talk about most common causes of seal failure and how…

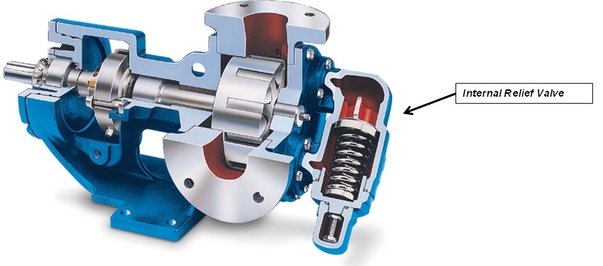

Do PD Rotary Pumps Require Pressure Relief Valve?

One day Mr. Pandey, operator at a chemical plant, was overseeing the raw material unloading from the truck to the storage tank. The pump for unloading this thick raw material was a positive displacement (PD) gear pump. Suddenly, the level gauge…

Online Tools (Unit Conversion, NPSHa calculations, Chemical Compatibility)

Though the world has become interconnected and there is standardization of most technological products, yet companies cling to the units they follow traditionally for various liquid/ system parameters. For example, some companies continue to use GPM and PSI for flow and…

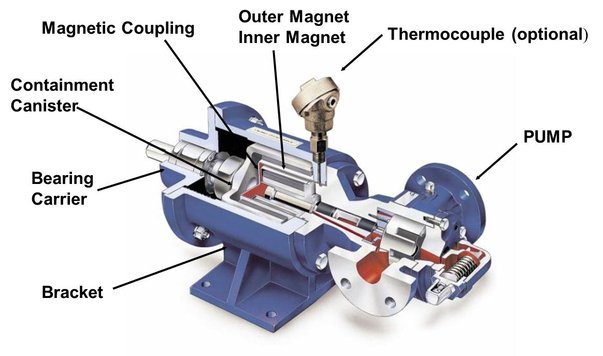

Mechanical Seal Problems? Consider Sealless Magnetic Drive PD Rotary Pumps

In a Dec 2008 survey of industrial pump users, top three of 12 identified needs were “eliminating leakage”, “simple installation, operation, and maintenance”, and “minimizing energy uses.” Any pump user will vouch that no. 1 cause of pump failure is mechanical…

New Pump Is Not Developing Pressure

Few years ago, Mr. Pandey, operations manager at a chemical plant, called me, “This new gear pump I bought from you a week back is no good.” I probed, “Pandeyji, why do you think this pump is not good?” After few…

Why This Blog

In our engagement with industry for the past several years, as one of the world’s largest manufacturers of PD pumps, we found that people value the wealth of knowledge we have. Every time we shared this it was well appreciated and…

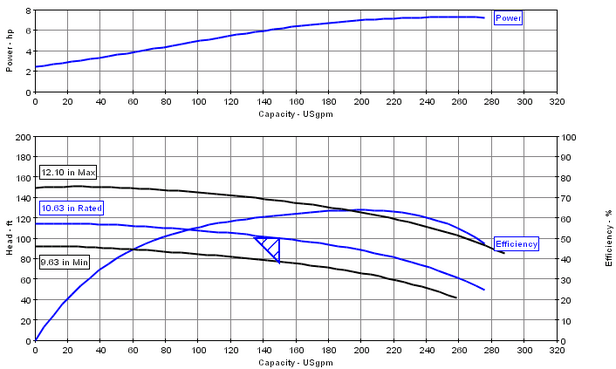

Can PD Pumps Handle Thin Liquids

The question begs asking, “Everyone knows centrifugal pumps are best suited for handling thin liquids. Why even bother whether PD pumps will work for such applications?” Before we address this, let’s first understand what thin liquids are. Thin liquids are liquids…